Turnkey Aerobic Treatment Plant

ISC constructed a 3.4 MGD, 3 phase aerobic treatment plant upgrade for Tyson Foods at their Noel, Missouri poultry processing facility. The High Rate Activated Sludge treatment plant was constructed to remove BOD, TSS and oil & grease from wastewater generated from slaughter and further processing operations.

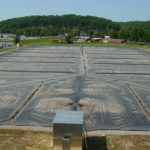

A floating lagoon cover system was installed at the facility for odor control and future biogas collection and reuse.

Integral Components:

- Continuous Mixed Aeration Sludge System

- Jet Mix Aeration System

- Final Clarifier

- Aerobic Tank Storage

- Anaerobic Tank Storage

- Floating Aeration

- DAF Effluent Pump Station

- DAF Effluent Pump Station

- Chlorine Contact Chamber

- Chemical Feed System

- Gas Recovery and Burning System

- Lagoon Lining System

- Floating Lagoon Cover System

- Equipment Building

Project Brochure

Download